IND-1000-28kHz

3.433,54 €

- 95 L stainless-steel tank (2 mm)

- Tank dimension: 600×400×400 mm

- 28 kHz frequency — powerful yet gentle cleaning

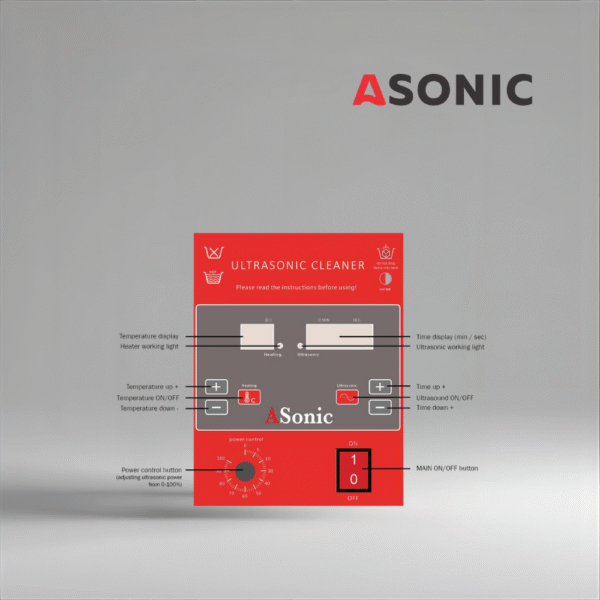

- Digital timer 1–99 min for convenient operation

- Adjustable ultrasonic power (0–100%) for optimal cleaning performance

- Adjustable heating up to 80°C

- Drain valve – easy liquid exchange without lifting

- Extended duty cycle — designed for continuous use, up to 12 hours/day for professional operations

- Mounted on wheels with stoppers for easy mobility and secure positioning.

Only 1 left in stock

ASONIC IND-1000-28kHz Industrial Ultrasonic Cleaner

95 L Ultrasonic Cleaner for Advanced Professional Users — Designed for Continuous 12h/Day Use

The ASONIC IND-1000-28kHz is a premium industrial ultrasonic cleaner designed for daily cleaning of larger components and batch loads in automotive, aerospace, manufacturing, maintenance, and laboratory environments. Engineered for precision, speed, and reliability, it delivers outstanding results even on complex geometries and intricate internal channels.

Featuring a 95-liter reinforced SUS 304 stainless-steel tank (2.0 mm hand-welded) and operating at 28 kHz low frequency, the IND-1000-28kHz produces powerful, energy-rich cavitation bubbles that rapidly dislodge oils, grease, carbon, polishing pastes, flux residues, and machining contaminants.

With 24 industrial-grade transducers delivering 1440 W of ultrasonic power, the system ensures uniform cavitation and consistent cleaning performance across the entire bath. A 3000 W heating system (adjustable up to 80 °C)enhances detergent efficiency, reduces cycle times, and supports high-throughput workflows, while an integrated drainage valve allows safe and convenient liquid exchange.

Built for continuous industrial use, the ASONIC IND-1000-28kHz combines robust construction, reliable operation, and superior cleaning performance, making it the ideal choice for professionals who demand efficiency and durability every day.

We also provide custom-built units tailored to specific dimensions and requirements — which can be equipped with advanced industrial options such as a lift system for automatic loading/unloading, a filtration system for extended bath life, an oil skimmer for separating contaminants, and programmable cleaning cycles for efficiency.

Why Choose the Industrial-Grade ASONIC IND-1000?

- High cleaning efficiency

- Professional-grade performance

- High productivity

- Heavy-duty construction

- Extended duty cycle

- Customizable options — available with pneumatic lift system, filtration unit, oil skimmer, programmable cleaning cycles, or 40 kHz frequency.

Industrial-Grade Features

- Compact 95 L capacity – perfectly suited for professional and industrial applications.

- Durable SUS 304 stainless-steel tank (2 mm hand-welded) – corrosion-resistant.

- Tank dimension: 600×400×400 mm – tank dimensions indicate the largest item you can clean, depending on how it’s positioned inside the tank.

- Digital timer (1–99 minutes) – ensures controlled, repeatable cleaning cycles.

- 28 kHz ultrasonic frequency (1440 W adjustable) – adjustable ultrasonic power (0–100%) for optimal cleaning performance.

- 24 transducers – (24 x 60W industrial transducer) ensures even distribution of ultrasonic waves.

- Integrated heating up to 80 °C – heater with 3000W for fast heating, warm the cleaning solution to a temperature suitable for the material and type of dirt.

- Integrated drain valve helps users easily pour out the water.

- Mounted on wheels – with stoppers for easy mobility and secure positioning.

- Engineered for reliable operation — designed for up to 12 hours of continuous daily use.

Applications

- Automotive & Mechanics — Industrial ultrasonic cleaners remove carbon, grease, and dirt from injectors, carburetors, brake parts, and engine blocks.

- Manufacturing & Machining — Large ultrasonic baths clean oils, polishing compounds, and residues from molds, machined components, and precision tools.

- Medical & Dental — Ultrasonic cleaning machines safely disinfect stainless steel instruments, dental tools, glassware, and laboratory equipment.

- Electronics & Precision Parts — Powerful ultrasonic cleaners wash PCBs, sensors, connectors, and delicate assemblies with complete precision.

- Aerospace & Aviation — Ultrasonic baths restore turbine blades, hydraulic parts, landing gear, and fuel system components with safe deep cleaning.

- Railway & Heavy Transport — Industrial ultrasonic cleaning removes grease and dirt from bearings, couplings, brake systems, and transmission parts.

- Marine & Shipping — Large ultrasonic cleaners eliminate salt, grease, and fuel residues from valves, propellers, pumps, and engine components.

- Food & Beverage Industry — Hygienic ultrasonic cleaning of filters, filling nozzles, heat exchangers, and stainless steel food processing equipment.

- Pharmaceutical & Biotech — Ultrasonic baths clean reactors, mixers, filling machines, and lab vessels under validated pharmaceutical standards.

- Oil & Gas / Energy — Ultrasonic cleaners restore valves, pumps, exchangers, and drilling tools exposed to scale, grease, and heavy residues.

- Printing Industry — Large ultrasonic cleaners remove ink, adhesives, and resins from rollers, print heads, and press components.

- Defense & Military — Ultrasonic cleaning systems maintain firearms, optics, and heavy weapon components with safe deep decontamination.

- Plastic & Mold Making — Industrial ultrasonic baths clean injection molds, extrusion dies, and tooling from oils and release agents.

- Restoration & Conservation — Ultrasonic cleaning safely removes corrosion, dirt, and residues from archaeological finds, coins, and metal artifacts.

Why Choose Ultrasonic Cleaning

- Time-saving: Thorough results in just a few minutes.

- Eco-friendly: Uses mostly water with minimal detergent.

- Safe & gentle: Effective on delicate items and hard-to-reach crevices.

How to Use

- Fill the tank with water (add approved cleaning solution if needed).

- For best results, warm the cleaning solution to a temperature suitable for the material and type of dirt.

- Place items in the basket, ensuring they’re fully submerged.

- Select the cleaning cycle and start; rinse and dry after completion.

Tip: Always check manufacturer guidance for sensitive stones, coatings, or electronics before ultrasonic cleaning.

Safety & Usage Notes

- Always operate with liquid in the tank.

- During heating, keep ultrasound running for even temperature distribution.

- Maintain liquid level ~2 cm below rim when loaded; always use the basket.

- Rinse and dry items thoroughly after cleaning, especially electronics.

Package Includes

- ASONIC IND Ultrasonic Cleaner

- Stainless-steel basket

- Stainless-steel lid

- Power cord

- User manual

Ultrasonic cleaners

ASONIC ultrasonic cleaners user manuals

Dimensions of the ASONIC ultrasonic cleaners

Cleaning detergents

ASONIC cleaning detergents MSDS

How to chose the right Cleaning Detergent for your application

Technical Specifications

| Specifications | Value |

|---|---|

| Ultrasonic power | 1440 W |

| Ultrasonic frequency | 28 kHz |

| Number of transducers | 24 |

| Timer (min) | 1 – 99 |

| Max temperature | 80°C |

| Heater power | 3000 W |

| Max tank volume | 95 lit. |

| Tank thickness | 2,0 mm |

| Basket dimensions (WxDxH) | 570×370×400 mm |

| Tank dimensions (WxDxH) | 600×400×400 mmx |

| Unit dimensions (WxDxH) | 730×530×700 mm |

| Package dimensions (WxDxH) | 890×630×840 mm |

| Discharge valve | YES 1″ |

| Max weight for lift | / |

| Filtration system | / |

| Oil Skimmer | / |

| Power plug | IEC309 (5pin, 380V) |

| Net. weight | 80 kg |

| Warranty (years) | 2 |

| Specifications | Value |

|---|---|

| Resonant impedance (Ω) | ≤15 |

| Capacitance (pF) | ±10%: 4100-4500 |

| Frequency | 28 kHz |

| Weight (g) | 425 g |

| Diameter | 60 mm |

| Height | 68 mm |

SOMETHING ABOUT US

Interesting Facts

Ultrasonic cleaning is a fascinating process that uses sound waves and millions of microscopic bubbles to reach places brushes or cloths can’t. It’s powerful enough to remove stubborn dirt and grease, yet gentle on delicate items like jewelry, lenses, and instruments. This eco-friendly method reduces the need for harsh chemicals, saves time, and is up to 16 times more effective than traditional cleaning – making it a trusted solution across many industries.

Gentle care

Safely cleans delicate jewelry, lenses, and instruments without causing any damage.

Microscopic bubbles

Sound waves create bubbles that clean even the tiniest hidden surfaces.

Highly effective

Ultrasonic cleaning is up to 16 times faster and more efficient than manual work.

Eco-friendly

Uses little to no harsh chemicals, making it safe for people and the environment.